@ Powered by www.300.cn © 2020 Superman Company. ALL Rights Reseruved.

浙ICP备16026603号

news

Create a "Made in China 2025 Zhejiang Action" Yongkang model

Release time:

2019/03/12 15:33

Page view

[Abstract]:

Under the overall spirit of the state and the province to promote "Made in China 2025", combined with the actual development and characteristic advantages of the manufacturing industry in the city, Superhuman Company actively implemented the leading force and contributed to the revitalization of Yongkang City's economy.

Nowadays, the city puts forward the goal of high-quality growth. The industrial economic growth mode is gradually changing from quantity to quality. The manufacturing industry of our city fully combines the “Made in China 2025” Zhejiang Action Demonstration Pilot and the province's revitalization of the real economy (traditional industrial transformation). ) Pilot, taking the pace of smart manufacturing and intelligent product development.

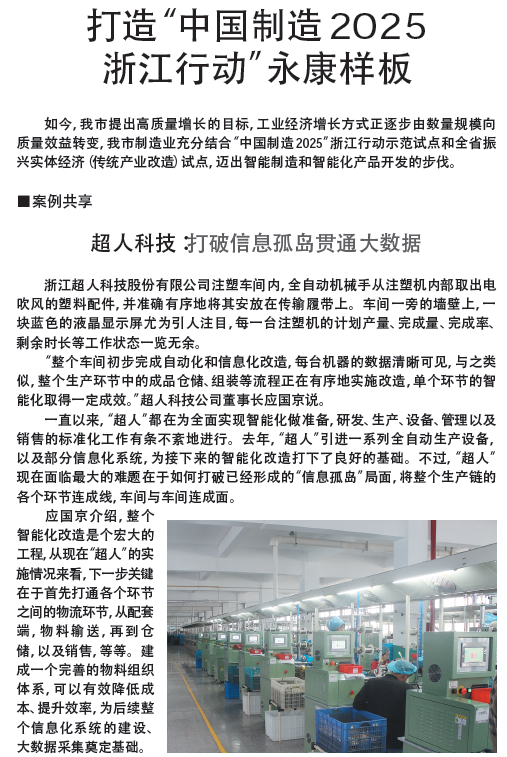

Superhuman Technology: Breaking information islands and breaking through big data

In the injection workshop of Zhejiang Superhuman Technology Co., Ltd., the fully automatic robotic arm takes out the plastic parts of the hair dryer from the inside of the injection molding machine and places them on the transmission track in an accurate and orderly manner. On the wall next to the workshop, a blue LCD screen is particularly eye-catching, and each injection machine’s planned output, completed amount, completion rate, and remaining time are unobstructed.

“The whole workshop has completed the preliminary automation and information transformation. The data of each machine is clearly visible. Similarly, the processes of finished product storage and assembly in the whole production process are being implemented in an orderly manner, and the intelligence of individual links has achieved certain results. "Superhuman Technology Company Chairman Ying Guojing said.

All along, "Superhuman" has been preparing for the full realization of intellectualization, and the standardization of R&D, production, equipment, management, and sales are carried out in an orderly manner. Last year, "Superhuman" introduced a series of fully automatic equipment, as well as some information systems, which laid a good foundation for the next intelligent transformation. However, "Superhuman" is now facing the biggest problem is how to break and form the "information island" situation, connecting all links of the whole production chain into a line and the workshop and workshop into a plane.

Superhuman Company is the first shaver production enterprise to build a dust-free workshop and also the first founder to step into the industrial 4.0 pace in China. The injection workshop uses water and electricity central feeding system and full robotic arm equipment, 24 hours of continuous production. The production and assembly of energy-efficient data acquisition and real-time feedback monitoring of computer systems, intelligent production management not only achieves maximum capacity, but also maximizes the stability of product quality.

打造工业4.0标准企业,与时代同行

Ying Guojing said that the entire intelligent transformation is a grand project. From the current implementation of "Superhuman", the next step is to open up the logistics links between the various links firstly, from the supporting end, logistics transportation, warehousing, and sales etc. The establishment of a complete material organization system can effectively reduce costs and improve efficiency for the subsequent construction of the entire information system. Big data collection lays the foundation.

Previous article:

Our company was invited to attend the AWE2019

Annual Major Events of Superman Technology in 2018

Next article: